Established in 2004, Chengdu Holy Tech Co., Ltd. has been at the forefront of capacitor innovation, specializing in aluminum electrolytic capacitors, conductive polymer capacitors, and super capacitors. With three manufacturing plants in China, the company covers an area of 1000 acres and employs over 400 workers, with an impressive annual production capacity of 2 billion pieces.

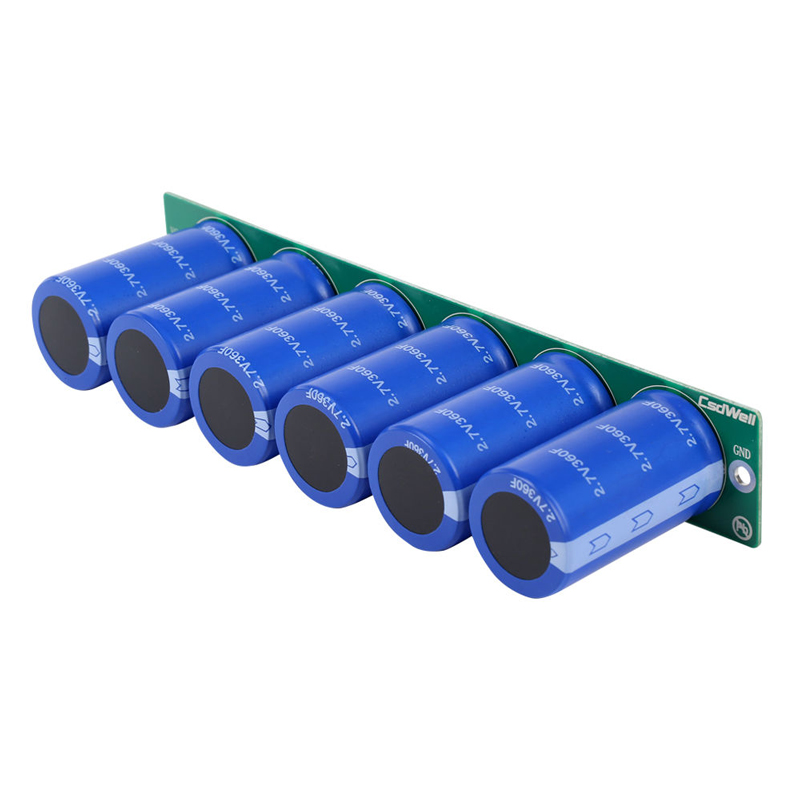

Super capacitors, also known as ultracapacitors, are energy storage devices that bridge the gap between conventional capacitors and rechargeable batteries. They are widely used in a variety of applications, including renewable energy, automotive, and consumer electronics. The development of laser welding technology for super capacitors is a significant advancement that is expected to enhance their performance and durability.

Traditional methods of assembling super capacitors involve the use of adhesives or mechanical connections to join the various components together. However, these methods have limitations in terms of reliability and longevity. Laser welding, on the other hand, offers a more precise and efficient means of bonding the components, resulting in a more robust and durable end product.

The new laser welding technology developed by Chengdu Holy Tech Co., Ltd. is expected to improve the overall performance of super capacitors by enhancing their electrical and thermal conductivity, as well as reducing their internal resistance. This will lead to more efficient energy storage and delivery, making super capacitors an even more attractive option for a wide range of applications.

In addition to the technical advantages, the adoption of laser welding for super capacitors is also expected to improve the manufacturing process. The use of automated laser welding systems will streamline production, reduce manufacturing costs, and improve overall product consistency and quality.

"We are thrilled to introduce this groundbreaking laser welding technology for super capacitors," said a spokesperson for Chengdu Holy Tech Co., Ltd. "This represents a significant step forward in capacitor technology and demonstrates our commitment to innovation and excellence in our industry."

The development of this new technology is the result of significant investment in research and development by Chengdu Holy Tech Co., Ltd. The company has a dedicated team of engineers and scientists who are continually working to push the boundaries of capacitor technology and develop new and innovative solutions for their customers.

The announcement of the new laser welding technology for super capacitors has generated a great deal of excitement within the industry, with many experts hailing it as a game-changer. The potential implications for the wider application of super capacitors in various industries are significant, as the improved performance and reliability offered by laser welding technology make them an even more attractive option for energy storage and delivery.

As Chengdu Holy Tech Co., Ltd. prepares to roll out this new technology, the company is confident that it will have a transformative impact on the industry. The future looks bright for super capacitors, and this latest development is set to cement Chengdu Holy Tech Co., Ltd.'s position as a global leader in capacitor technology.

In conclusion, Chengdu Holy Tech Co., Ltd.'s development of laser welding technology for super capacitors represents a significant advancement in capacitor technology. This breakthrough is expected to improve the performance and reliability of super capacitors, making them an even more attractive option for a wide range of applications. As the company prepares to introduce this new technology to the market, the industry is abuzz with anticipation for the transformative impact it is set to have.